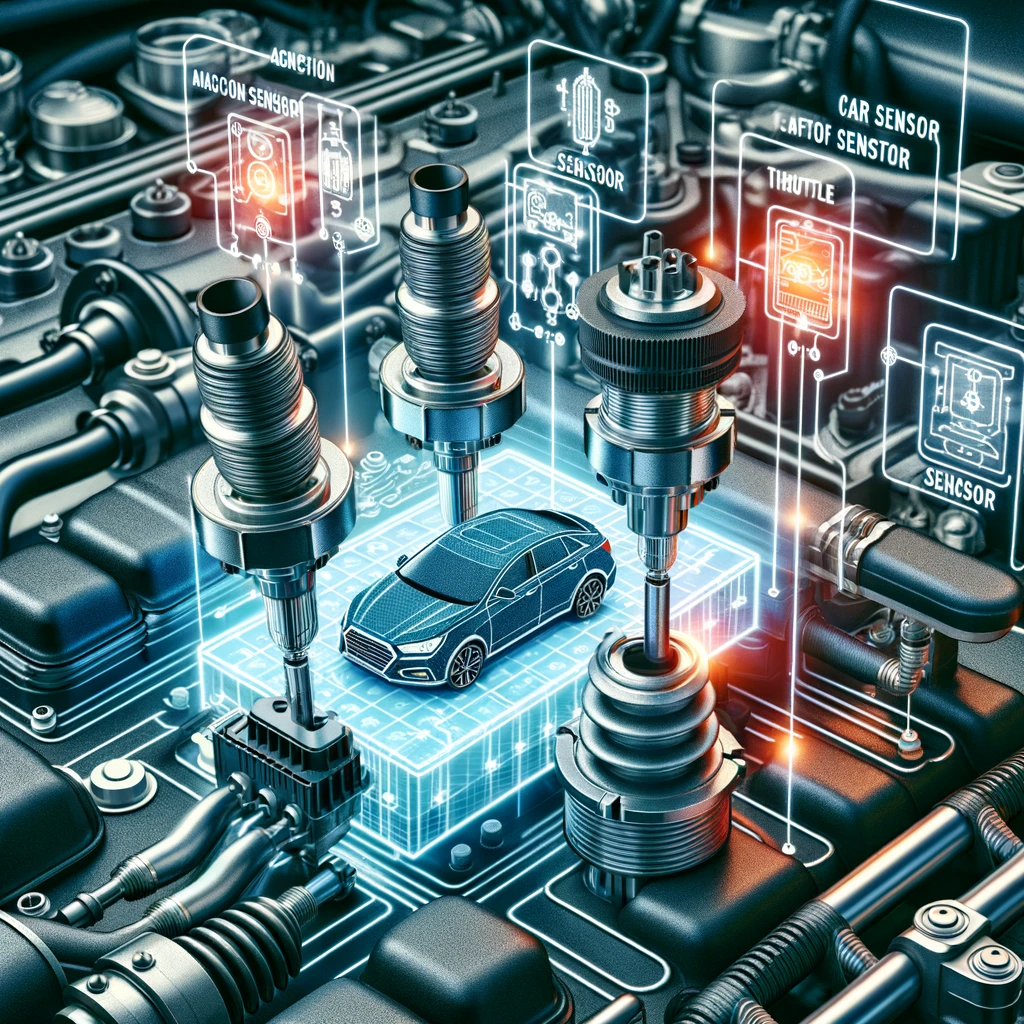

Sensor Malfunctions: The ECM relies on a network of sensors to make decisions. If sensors like the oxygen sensor, mass airflow sensor, or throttle position sensor malfunction, it can lead to incorrect data being fed to the ECM, causing performance issues.

The Engine Control Module (ECM), often referred to as the engine control unit (ECU), is the brain of a vehicle. It’s a sophisticated computer system that plays a crucial role in managing the engine’s operations, ensuring optimal performance, fuel efficiency, and emissions control. The ECM’s decision-making is heavily reliant on a network of sensors that provide real-time data about various engine parameters.

Each sensor in the network serves a specific function. For instance, the oxygen sensor measures the oxygen level in the exhaust gases, informing the ECM about the engine’s combustion efficiency. This data is crucial for regulating the air-to-fuel ratio, ensuring that the engine runs efficiently and emissions are minimized.

Another key sensor is the mass airflow (MAF) sensor, which measures the amount of air entering the engine. This information is critical for the ECM to calculate the right amount of fuel for efficient combustion. A malfunction in the MAF sensor can lead to a range of issues, including poor fuel efficiency and engine performance problems.

The throttle position sensor (TPS) is equally important, providing the ECM with data about the position of the throttle valve. This sensor plays a vital role in controlling the engine’s air intake, which is directly linked to acceleration and power output.

These sensors, along with others like the crankshaft position sensor, coolant temperature sensor, and manifold absolute pressure sensor, form an intricate network that feeds the ECM with necessary data. The ECM processes this information to control various engine functions, such as fuel injection, ignition timing, and idle speed control.

The reliability of these sensors is paramount, as any malfunction can lead to incorrect data being fed to the ECM. This can result in a range of engine performance issues, from poor fuel economy and increased emissions to engine misfires and reduced power output. It underscores the importance of regular maintenance and prompt attention to any engine warning signals, often indicated by the check engine light.

Oxygen Sensor Malfunctions

Oxygen sensor malfunctions in vehicles can lead to a variety of engine and performance issues, as these sensors play a critical role in the engine’s emission control and combustion process. An oxygen sensor, often referred to as an O2 sensor, is responsible for measuring the oxygen content in the vehicle’s exhaust gases. The data from this sensor is crucial for the Engine Control Module (ECM) to adjust the air-to-fuel ratio, ensuring efficient combustion and minimizing harmful emissions.

When an oxygen sensor malfunctions, it can send incorrect information to the ECM, leading to a range of problems. One common issue is rough idling, where the engine runs unevenly or stalls at idle. This happens because the ECM is not receiving accurate data on the exhaust gas composition and cannot adjust the fuel mixture correctly.

Another significant consequence of a faulty oxygen sensor is increased gas emissions. Since the sensor is key in controlling the vehicle’s emission levels, its malfunction can lead to higher emissions of pollutants, which not only harms the environment but can also cause the vehicle to fail emissions tests.

Perhaps one of the most severe impacts of a bad oxygen sensor is the potential damage to the catalytic converter. The catalytic converter is an essential component that reduces harmful emissions from the exhaust system. If the oxygen sensor feeds incorrect data to the ECM, it can cause the engine to run too rich (too much fuel) or too lean (too little fuel). Running rich can lead to unburned fuel entering the catalytic converter, causing it to overheat and potentially fail. On the other hand, running lean can cause engine misfires, putting additional strain on the catalytic converter.

Oxygen sensor issues can also manifest as performance problems, such as a noticeable decrease in fuel efficiency and engine power. The ECM relies on accurate sensor data to optimize fuel delivery and ignition timing, and incorrect readings can lead to suboptimal combustion, affecting the vehicle’s performance.

To diagnose an oxygen sensor malfunction, mechanics often rely on diagnostic trouble codes (DTCs) from the vehicle’s onboard diagnostics system (OBD-II). Common DTCs related to oxygen sensors include codes like P0147 and P0141, indicating heater circuit malfunctions in specific sensors. Resolving these issues typically involves replacing the faulty sensor and ensuring the engine and exhaust systems are functioning correctly.

Oxygen sensors are vital for vehicle engine performance and emission control. Malfunctions in these sensors can lead to increased emissions, reduced fuel efficiency, potential catalytic converter damage, and overall poor engine performance. Regular maintenance and timely diagnostics are key to ensuring these sensors function correctly, helping to maintain optimal engine performance and adherence to emission standards

Mass Airflow Sensor (MAF) Issues

Mass Airflow Sensor (MAF) issues are a common cause of engine performance problems in vehicles. The MAF sensor plays a critical role in the vehicle’s engine management system by measuring the volume and density of air entering the engine. This information is crucial for the Engine Control Module (ECM) to calculate the appropriate amount of fuel to inject for optimal combustion.

When the MAF sensor malfunctions, it can lead to a variety of issues. One of the most noticeable symptoms is poor fuel efficiency. This happens because the ECM, receiving incorrect data about air intake, may inject more or less fuel than needed, leading to an imbalanced air-to-fuel ratio. As a result, the vehicle may consume more fuel than usual.

Another common symptom of a faulty MAF sensor is rough idling. This occurs when the engine receives an incorrect air-to-fuel mixture, causing it to run unevenly or stall. Drivers may notice that the engine vibrates more than usual or seems to struggle to maintain a consistent speed while idling.

Reduced engine power is also a frequent consequence of MAF sensor issues. Inaccurate air flow readings can lead the ECM to limit fuel delivery, reducing the engine’s power output. This can be particularly noticeable during acceleration, where the vehicle may feel sluggish or unresponsive.

In some cases, a malfunctioning MAF sensor can lead the engine to run lean (too much air and not enough fuel) or rich (too much fuel and not enough air). Running lean can cause the engine to hesitate or surge, particularly under load, while running rich may lead to a noticeable fuel smell from the exhaust, as unburned fuel is emitted.

To diagnose and resolve MAF sensor issues, mechanics often start by examining the sensor for dirt, debris, or damage. Sometimes, simply cleaning the sensor can resolve the problem. However, if the sensor is faulty, replacement may be necessary. It’s also important to check for any air leaks in the intake system, as these can also cause inaccurate readings.

Regular maintenance and timely attention to any changes in engine performance can help prevent or quickly address MAF sensor issues. Keeping the air filter clean and ensuring the integrity of the air intake system are crucial steps in maintaining the proper function of the MAF sensor.

Throttle Position Sensor (TPS) Problems

Mass Airflow Sensor (MAF) issues are a common cause of engine performance problems in vehicles. The MAF sensor plays a critical role in the vehicle’s engine management system by measuring the volume and density of air entering the engine. This information is crucial for the Engine Control Module (ECM) to calculate the appropriate amount of fuel to inject for optimal combustion.

When the MAF sensor malfunctions, it can lead to a variety of issues. One of the most noticeable symptoms is poor fuel efficiency. This happens because the ECM, receiving incorrect data about air intake, may inject more or less fuel than needed, leading to an imbalanced air-to-fuel ratio. As a result, the vehicle may consume more fuel than usual.

Another common symptom of a faulty MAF sensor is rough idling. This occurs when the engine receives an incorrect air-to-fuel mixture, causing it to run unevenly or stall. Drivers may notice that the engine vibrates more than usual or seems to struggle to maintain a consistent speed while idling.

Reduced engine power is also a frequent consequence of MAF sensor issues. Inaccurate air flow readings can lead the ECM to limit fuel delivery, reducing the engine’s power output. This can be particularly noticeable during acceleration, where the vehicle may feel sluggish or unresponsive.

In some cases, a malfunctioning MAF sensor can lead the engine to run lean (too much air and not enough fuel) or rich (too much fuel and not enough air). Running lean can cause the engine to hesitate or surge, particularly under load, while running rich may lead to a noticeable fuel smell from the exhaust, as unburned fuel is emitted.

To diagnose and resolve MAF sensor issues, mechanics often start by examining the sensor for dirt, debris, or damage. Sometimes, simply cleaning the sensor can resolve the problem. However, if the sensor is faulty, replacement may be necessary. It’s also important to check for any air leaks in the intake system, as these can also cause inaccurate readings.

Regular maintenance and timely attention to any changes in engine performance can help prevent or quickly address MAF sensor issues. Keeping the air filter clean and ensuring the integrity of the air intake system are crucial steps in maintaining the proper function of the MAF sensor.

Diagnostic Trouble Codes and Mechanics’ Role

Diagnostic Trouble Codes (DTCs) are critical tools in modern vehicle diagnostics, playing a vital role in helping mechanics identify and resolve issues within a vehicle’s engine and other systems. These codes are generated by the vehicle’s onboard diagnostics system (OBD-II), which monitors the performance of various components and sensors. When the system detects a malfunction, it logs a specific code that corresponds to the nature of the problem.

Each DTC consists of a letter followed by four digits. For example, a code starting with ‘P’ relates to the powertrain, which includes the engine, transmission, and associated components. Codes starting with ‘B’, ‘C’, and ‘U’ indicate issues related to the body, chassis, and network communication systems, respectively.

A mechanic’s role in interpreting and acting on these codes is crucial. The first step typically involves using a scan tool or a code reader to retrieve the codes from the vehicle’s computer. These tools are plugged into the OBD-II port, usually located under the dashboard.

Once a code is retrieved, the mechanic can reference it against a database of known issues to understand the probable cause of the problem. For example, codes like P2074, P0227, P0147, and P0141 indicate issues related to the mass airflow sensor, throttle position sensor, and oxygen sensors, respectively. However, DTCs alone do not provide a complete diagnosis; they merely point the mechanic in the right direction.

The mechanic’s expertise comes into play in interpreting these codes in the context of the vehicle’s overall condition. They conduct further testing and inspections to confirm the root cause of the problem. For instance, a code indicating a malfunctioning oxygen sensor might lead the mechanic to inspect the sensor itself, the wiring connected to it, and related components like the catalytic converter.

Repairing the issue often involves replacing faulty parts, repairing damaged wiring, or reprogramming the vehicle’s computer. After the repair, the mechanic will typically clear the DTC from the system and may take the vehicle for a test drive to ensure that the issue has been resolved.

The role of DTCs and mechanics in vehicle diagnostics exemplifies the integration of technology and human expertise in modern automotive maintenance. While the codes provide valuable insights into the vehicle’s issues, the mechanic’s knowledge and experience are essential for accurate diagnosis and effective repair.

Preventative Measures and Maintenance Tips

Preventative measures and maintenance are key to ensuring the longevity and optimal performance of a vehicle. Regular maintenance not only helps in avoiding major repairs down the line but also ensures that the vehicle runs efficiently and safely.

One of the fundamental aspects of vehicle maintenance is regular oil changes. Engine oil lubricates the moving parts of the engine, reduces friction, and helps in heat dissipation. Over time, oil breaks down and loses its effectiveness, potentially leading to engine damage. The frequency of oil changes depends on the vehicle and type of oil used, but a general guideline is every 3,000 to 5,000 miles.

Replacing air filters is another critical maintenance task. Air filters prevent dust and other particles from entering the engine, ensuring clean air for combustion. A clogged air filter can reduce engine efficiency and performance. It’s generally recommended to check the air filter every 12,000 miles and replace it if necessary.

Tire maintenance is also crucial for safety and efficiency. This includes regular tire rotation, alignment checks, and maintaining proper tire pressure. Incorrect tire pressure can lead to uneven tire wear and reduced fuel efficiency, while improper alignment can cause handling problems and increased tire wear.

Checking and maintaining fluid levels is also vital. This includes not only engine oil but also coolant, brake fluid, power steering fluid, and transmission fluid. These fluids play critical roles in the vehicle’s operation and, if low or degraded, can lead to component failure and costly repairs.

Brake system maintenance is essential for safety. This includes checking the brake pads, discs, and fluid. Worn brake pads or discs can significantly reduce braking efficiency and increase stopping distances.

Battery maintenance is another important aspect. A weak or failing battery can leave you stranded. Check the battery’s charge level, clean the terminals to prevent corrosion, and ensure the connections are tight.

Finally, it’s important to heed warning lights and perform regular diagnostic checks. Modern vehicles are equipped with sophisticated systems that monitor vehicle performance. Addressing warning lights promptly and performing regular diagnostics can catch potential issues before they become major problems.